All products:

Where is?

424006, Mari El,

Yoshaker-Ola, Kokshaysky st., 30

Phones:

(8362) 45-19-50

(8362) 56-67-40

E-mail:

remstroy12@gmail.com

451950@mail.ru

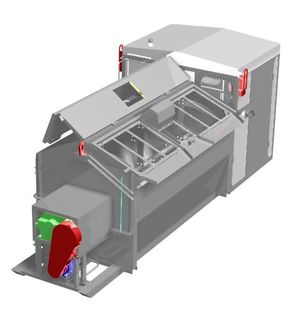

The plaster machine station SHS-4/6-3

The plaster machine station SHS-4/6-3 - type "SALUTE" " - is intended for reception of a solution (or a rigid solution, depending on mortar (concrete) pump) from a dumper, hashing, heating during storage on object, promptings, the filtering, the mechanized submission and spray application of a plaster solution on a work surface by injectors and, as required, deliveries in the elevating bunker or solution box in which moves on a workplace of the bricklayer. The station is applied on the open areas of units of industrial, civil and farm construction provided by the electric power and water

The plaster machine station SHS-4/6-3 - type "SALUTE" - is a metal construction which consists of the general frame, reception bunker, cabin the operator (engine room). The complete of the process equipment is placed in last, where work direction of station is carried out from a direction case.

Climatic modification V category I in accordance with GOST 15150 at an ambient temperature from a minus 30°С up to plus 40°С. At negative temperature of external air by the consumer should be provided reliable heat insulation of mortar (concrete) wire and systems of water supply.

Characteristics:

| Indicator | Units. | Value |

| Reception bunker volume | m3 | 4,0 |

| Endless screw diameter | mm. | 1480 |

| Rotation frequency of endless screw | min-1 | 15 |

| Productivity | according to mortar pump | |

| Hot-air generator power | kW | 5 |

| The electric motor capacity of endless screw drive | kW | 7,5 |

| Heaters | kW | 15 |

| The general established capacity | kW | 33,5 - 37 |

| Machine overall dimensions | ||

| – Length | мм. | 5670 |

| – Width | мм. | 2455 |

| – Height | мм. | 2270 |

| Weight , not less | кг. | 4000 |

The structure of a set of hoses depends on type mortar pump.

Mortar pump characteristics:

| The name | Units | СО-49S | СО-49PA | СО-49P2 | СО-50D | СО-50DM | СО-49D | СО-50PB (rigid solutions) |

| Productivity | m3/hour | 3,0 | 4,0 | 3,0/4,0 | 6,0 | 6,0 | 4,0 | 8 |

| Solution clipper | ОР-50 | |||||||

| − Dу | mm. | - | 50 | - | - | - | - | - |

| − pressure (max) | MPa. | - | 4,5 | - | - | - | - | - |

| Ball stopcock: | ||||||||

| − Dу | mm. | 38 | 38 | 38 | 38 | 38 | 65 | |

| − pressure (max) | MPa. | 4,0 | 4,0 | 2,5 | 2,5 | 1,6-2,5 | 4,0 | |

| Working presure (max) | kgs/sm2 | 35 | 35 | 30 | 25 | 25 | 15 | 30 |

| Submission distance of a solution: | ||||||||

| – across horizontal, no more | m. | 250 | 300 | 250 | 250 | 250 | 160 | 200 |

| – across vertical, no more | m. | 100 | 120 | 80 | 60 | 60 | 35 | 50 |

| Piston motion | mm. | 90 | 120 | 90 | - | - | - | 120 |

| Plug motion | mm. | - | - | - | 120 | 120 | 90 | - |

| Cylinder sleeve lenght | mm. | 188 | 220 | 188 | - | - | - | 220 |

| Piston diameter | mm. | 100 | 100 | 100 | - | - | - | 150 |

| Plug diameter | mm. | - | - | - | 110 | 110 | 90 | - |

| The hatch for replacement of the ball | - | + | - | - | - | - | + | |

| Oil crankcase of gear pair | - | - | - | - | + | - | - | |

| Rubber-covered ball, diameter | мм. | 50 & 70 | 50 & 70 | 50 & 70 | 70 & 70 | 70 & 70 | 60 & 60 | 70 & 100 |